The kitchen renovation continues and this, my third project is all about the range hood. I needed to build and install a range hood that could take all those cooking fumes outside the house.

Well, you have to stick around because I'm very proud of the range hood that I built and I have all the details for you!

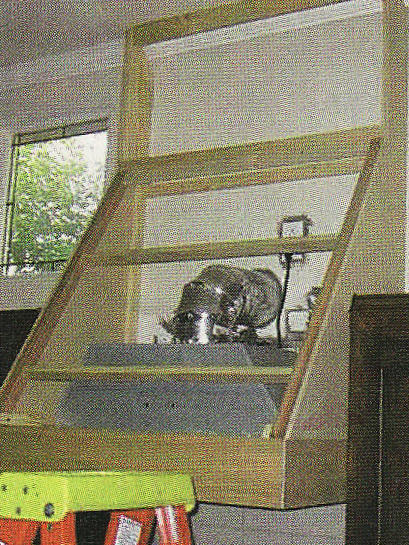

That recirculating fan that we had and that you can see in the picture below was simply gross. 🤢

Now, for this range hood, which was a high priority, I knew exactly what I DIDN'T want.

Yes, sometimes' easier to check off the things we don't like to find out what we really want. ;)

I didn’t want a recirculating unit, I just hate don’t like them.

What I DID want here in my kitchen was a custom-looking range hood. They usually have a big tag price and that's why I searched high and low on how to build it myself.

At the time I was renovating my kitchen, which happened to be circa 2010, there wasn't a single tutorial online. But guess what? I found a way on how to build it and install it myself, with my own two hands, and that's the range hood that we've used for more than 10 years already.

*This post contains affiliate links for your convenience. Click here to read my full disclosure policy.

So many years had passed for me wanting to tackle this project. Every time I cooked, especially something “fishy” and your whole house stinks 😝 Finally, the time arrived!

It was a pleasure for me to get rid of that old re-circulating hood. I think they should be banned. The cabinet on top of the range was also removed.

This is how the building and installing of the range hood went:

Price was important but also efficiency and look. After reading many reviews, I kind of settled on two models of Range Hood Inserts (that’s what they are called when you are going to provide a cover for it):

In the end, these are the parts that I got:

My lucky break for building this range hood came my way via The Family Handyman Magazine Feb/10 issue. There, one of its readers, Mr. Tom Pollard shared his very own project.

These two pictures and a brief explanation were all I needed to tackle this project!

1. BUILD & INSTALL THE TRAY

I began by building a tray or drawer out of 3/4" plywood and pine. Plywood was used for the big plate and pine for all the sides.

This tray is the lower part of the range hood. The part that you'll see when looking up from the stove.

This is the part that would hold the exhaust system. You want it to be strong.

There in the center, and following the manufacturer's instructions, I drew the exhaust system location. Then, using a jigsaw, that rectangle was cut out.

These were the dimensions I used.

Then, the tray or drawer was installed.

Once again, I followed the manufacturer's instructions on how high or low I needed to install it.

Make sure to drill the long screws onto the studs on the wall and a set of shorter screws onto the cabinets on each side (front frame).

2. CUT & INSTALL THE SIDE PANELS

The sides panels (not shown), were cut and installed securing them to the side of the cabinets and to the back wall.

I used 1/2" MDF for these panels. They looked like a right-angle trapezoid with one side's length of 25-1/4", the other 19", the other 12. The fourth side is the diagonal.

Here is the sketch of what the final hood had to look like:

Install the hood, which is mainly sitting the unit there on the tray, secure it with the included screws.

4. INSTALL THE HOOD LINER ON THE BOTTOM SIDE OF THE TRAY.

5. RUN THE DUCTING

I couldn’t run the vent pipe to the outside through that back wall because on the other side of that wall is my dining room.

The only way to run the duct pipe to the outside was by fitting it up to the top and connecting an elbow to go on top of the cabinets and then to the outside on the left.

For this model the required 6” round metal duct pipe and wall cap can be found at most home centers.

|

| Broan wall cap |

You need to open a hole on an outside wall to bring the vent pipe to the outside of the house.

I was a bit scared doing that. But hey, find the spot where you want to open that hole, make sure there aren't studs or electrical work there. Then, there inside the house/kitchen drill a small hole in the center of that area, go all the way through.

Go outside and find that hole and draw the 6" circle around it. Make sure it's a clear spot out there.

Cut out the 6" circle inside the kitchen (drywall), then go out and do the same on the outside (siding or brick).

The opening on the wall was made, the wall cap was installed, and the ductwork joints were sealed with foil tape until connected to the exhaust system. My husband helped me a lot during this entire hood process. He installed an electrical outlet right behind the enclosure because this system had to be grounded.

6. CLOSE THE HOOD

6. CLOSE THE HOOD

After installing the hood system and checking that everything was in good working order, a "frame" made out of 1 x 2 pine material (it looked like a little ladder), was attached to the side panels, as you see in my inspiration picture below.

That "ladder" is the one that's going to give support to the top cover.

The butt joints on the sides were sanded very well before priming and painting it. And there was a little gap at the bottom, that was hidden with wooden moldings that I installed later on.

The picture below gives you an idea of how it should look at the end of the day.

You can check my next post to see the MOLDINGS that were installed not only here on the range hood, but on the cabinets as well.

This is how this range hood looked at the end of the entire renovation:

As I said before, we've been using this range hood for many years already. It has served us well.

I'm glad I went for it and came up with this pretty addition to our kitchen.

You can check my complete review about the Broan PM390 Range Hood Insert right HERE.

|

| | Pendant Light | Chairs | Roman Shade | Drum Shade | Curtains - similar | |

The range hood was finished! :) The next project:

After almost five years of living with this range hood, I gave it a little makeover.

You can read everything about this range hood update right HERE.

Stay tuned for the next project: How to close the space above the cabinets

For more DIY Kitchen ideas check these out:

how to paint the cabinets.

Install a marble backsplash.

Build a fridge enclosure.

Update the kitchen island

Tips about installing recessed lights

Final kitchen reveal

Kitchen cost breakdown

1½ Year Later How the kitchen is Holding up

*This post contains affiliate links.

Amazing

ReplyDeleteThis is going to be very helpful when I am doing this myself

ReplyDeleteYou and your huband are rockstars!!!

ReplyDeleteI can't tell you how informative this has been...many thanks. After many years of relying on my very, very handy husband (we are currently fighting a battle for his life) I know that in spite of my limitations Rheumatoid Arthritis, I can tackle anything...this included. Thank you for the inspiration!!!!!

ReplyDeleteThank you for visiting! I whish you and your husband are doing well! Yes! all this is doable! and yes you can!

Deletewould this built-in from ikea work with this project? http://www.ikea.com/ca/en/catalog/products/70299563/

DeleteYep, that's the same concept.

DeleteSo beautiful!

ReplyDeleteThis is such a great project! I'd love to have this in my kitchen! Hopped over from the Impossibilities party!

ReplyDeleteWish I'd seen this about 4 years ago! :-) Nice job! I'm pinning it.

ReplyDeleteVery nice! Love the tile too.

ReplyDeleteI love it and I love your backsplash, can you tell me about it?

ReplyDeleteAwesome! I came out soooo great, and I love your back splash tile! Thanks so much for linking up!! Karah

ReplyDeleteYou go girl!! That is one serious project - so glad you joined our Impossibilities Challenge!

ReplyDeleteKelly

Beautiful kitchen. Love the cabinets painted white and the molding. Thanks so much for joining our Impossibilities challenge!

ReplyDeleteLinda

itallstartedwithpaint@gmail.com

You are Miss Talented!! This turned out gorgeous!

ReplyDeleteVery helpful! Thanks.

ReplyDeleteOH MY GATOS!!!

ReplyDeleteThis is AWESOME!!!!

You have just inspired me to do my own vent hood cabinet!

This is exactly what I wanted to know these days.

ReplyDeleteVery helpful. Reading and reading again all the projects you've done.

You're amazing and inspiring many of us who want-to-be DIYers.

Could you possibly -if you have a moment-explain more details about making a hole for duct and installing the wall cap?

Is this also doable job for anyone or need to hire someone professional?

Thank you so much.

The easiest way would be if you can open the hole right behind the system or up to the roof! The way to open the hole depends on what material your exterior walls are made of? My exterior walls are covered with aluminum siding. I began cutting (with a drywal knife) a 6" diameter circle, inside, in the kitchen; cut through the drywall until I reached the siding. I made a mark right in the center, so then, I went out and with the marked center I had, I drew the 6" circle on the siding to be cut, here I used a jig saw. Make sure the wall cap fits nicely before installing it. Then put plenty of Silicone on the parts of the wall cap that are going to be in contact with the wall. You can pick a color of silicone that matches your exterior wall. Finally you can screw it in place! Remember, before cutting anything make sure and, doble sure that no studs are in your way!

DeleteThank you,Cristina. Your explanations are like step by step how-to. Love it. Now time to get hands dirty. Thanks,again.

ReplyDeleteLove your site....gleam a lot of from it and will corporate them into my kitchen ideas for our remodel next year.

ReplyDeleteThis is such a fantastic tutorial. Thanks you so much for sharing it. :) Megan

ReplyDeleteanother to do!!! genious!

ReplyDeleteBeautiful...great job...

ReplyDeletewhat are the angles on that things? that's the most difficult thing when building it.

ReplyDeleteJohnny, First let me tell you I'm a rookie at building stuff like this one. I did it, it worked and that's why I wrote about it. I didn't bother about angles (that was way out of my league!).

ReplyDeleteThe bottom pan was installed, then the sides were installed, knowing that at the top they had to be 11½" and at the bottom 18½".

With the side panels in place I measured and cut the front. Straight cuts! There's a very small gap at the top and bottom but that was covered later on with the moldings.

OH, THANK YOU for posting this! I absolutely hate the un-ducted range hood we have. The filter & fan are on a 30° angle down toward the back wall, so that any grease particulates gather and run down onto my newly-installed stone backsplash (that I worked so hard on!), and have stained the top 3 inches of the SEALED grout, under the fan. (There was another article in Family Handyman about how to clean grease marks off of grout, but I have to wait until the hood is replaced before I bother doing that. Love that magazine - it's the only one I subscribe to!) I am doing this!

ReplyDeleteYou mention a manufacturer, can you give me a link to them. Also what is the hood made of? I don't mean the box/drawer you made but the dark brown part. Thank you!

ReplyDeleteThe insert and the liner are Broan products but I bought them through AMAZON : http://www.amazon.com/Broan-PM390-Power-Insert-Silver/dp/B000R9CFL6/ref=sr_1_1?ie=UTF8&qid=1378308876&sr=8-1&keywords=broan+range+hood+insert

ReplyDeleteThe dark brown part is MDF. I also use MDF to cover the open space above the cabinets, it's a great surface to be painted.

would this built-in from ikea work with this project? http://www.ikea.com/ca/en/catalog/products/70299563/

DeleteThank you! I'm currently down to the studs in part of my kitchen, having taken the wall out between kit ans DR. Love this range hood! Did you just make the box the size of the area available, between your cabinets?

ReplyDeleteThanks, Wow, you're in the middle of it all! Yes, I made the box to fit the available area, the same size as the cabinet that was holding the old re-circulating hood. Hey you're a no-reply I cannot reply directly to your e-mail address.

ReplyDeleteHow do I change that? I looked at settings but can't figure it out!

ReplyDeleteIdk

ReplyDeleteCristina, Your site has inspired me in so many ways. I know this is an old post of yours - I have had it "Pinned" for a long time - but we are in the midst of putting in a whole new kitchen ourselves, and I am getting ready to build a range hood cover similar to yours. Now that I'm ready to build I have a question: I am trying to understand why you put a "top" on the pine part of the frame, that holds the liner in place? It seems to be very sturdy, itself, and it comes with screws to attach it to the pine box that surrounds it. We have it assembled, with the blower in place, and it is supporting it very well. Is it absolutely necessary to support it with plywood, too, or was this just an extra precaution on your part? I haven't been over to Family Handyman, yet, so maybe this is the way that man did his? Thanks for your help.

ReplyDeleteThanks Laura! That box, especially the plywood, is what holds the exhaust system. I didn't think the liner was strong enough. Maybe they're selling stronger liners nowadays, or perhaps it was, as you said, an extra precaution on my part because yeah, the liner has screws to attach it to the pine box. Better safe than sorry. ;) The family Handyman article I mentioned doesn't have much explanations, just the two pictures I included here. I would love to see pics of your kitchen re-do.

DeleteChristina, this is a great post...and my wife is thrilled to do this in our kitchen! Quick question, how did you attach the side boards to the top (12" part)? Also, what size of boards did you use? Thanks in advance!

ReplyDelete-allen (allenoliver@gmail.com)

Ooops sorry for the late response! The sides are only attached to the cabinets on each side. They're not attached to the top board. For how I installed that top board you gotta check the link of how to cover the space above the kitchen cabinets. The side boards are ½" MDF.

DeleteOh, thank you, that was my same question. We're doing this project now - you've inspired us! We will be covering the top of the cabinets as well and I wondered if we had to have something to attach the top to before we completed this part. I hope you don't mind if I borrow LIBERALLY from your design. Am giving you full credit and links on my blog at 7yearswitchhome.com. You are literally my current hero.

DeleteI am so doing this!

ReplyDeleteOne question on the hood - did you miter the sides of the hood and front to make them fit together so gorgeously, or did you use 90 degree angles and fill them somehow? My husband said making a miter cut that long will be difficult.

ReplyDeleteOh hi Janessa, I just read this and your previous comment. I'll be stopping by your blog in a minute to see your work. ;)

DeleteNo, I didn't miter the sides of the hood, the whole thing is at an angle and that's totally out of my league! Those were all butt joins that were sanded a lot to smooth out the finish on the sides. There's a pic of the hood in this post: https://goo.gl/XqUaag, where you can see how the sides look.

Thank you so much Cristina! I can’t believe those are butt joints, they look so CLEAN. My husband started on the range hood this weekend and I was holding your blog open in Lowe’s looking at trim. (I hate to be a copycat but on the other hand why mess with perfection?!) So grateful for your blog!

DeleteGreat job on your hood! Are you happy with the insert you put in?

ReplyDeleteThanks Monique! Yes, I'm happy with it. It does the job that's supposed to do, but it's nothing fancy. It's somewhat noisy, especially on the highest settings, however, I've gotten used to it and I hardly ever use those highest settings.

Delete